Filter by price

Shop warning signs made in the UK

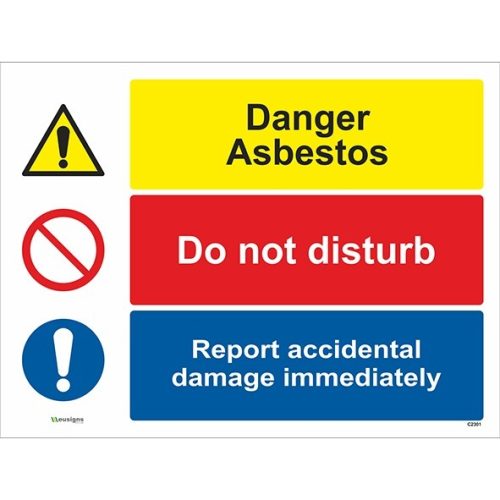

Get straight to the point with category-leading safety signage that people recognise instantly and act on without hesitation. We design and manufacture our warning signs in Britain for tough environments, clear visibility, and zero-nonsense compliance. You’ll get crisp pictograms, high-contrast yellow triangles, and durable materials that stand up to weather, solvents, and forklift traffic. Because accidents don’t wait, we produce fast, keep quality tight, and follow the standards that matter: BS 5499 & EN ISO 7010. Need bespoke sizes, multi-language text, or your asset IDs added? No problem. Order today, keep your site legally covered, and make it obvious where the risks are—before anyone gets hurt.

Meaning, colour, and when the law requires them

Let’s be clear: the yellow triangle means “Risk ahead—take care.” That’s the visual language defined by BS 5499 & EN ISO 7010, and it exists so a contractor from Belfast and a visitor from Berlin both interpret the same message in under a second. You must place warning signs wherever a significant hazard remains after you’ve taken reasonably practicable controls. Typical triggers include live electrics, deep excavations, overhead loads, corrosive substances, slippery surfaces, entanglement points, lasers, X-ray rooms, and high noise. The Health and Safety (Safety Signs and Signals) Regulations 1996 back this up; when there’s residual risk, sign it—consistently, legibly, and at the decision point, not down the corridor. Do your risk assessment, list each hazard, match the correct ISO 7010 symbol, and position the sign so it’s in the worker’s line of sight just before exposure. Then check lighting, mounting height, and contrast so nobody can reasonably miss it. For reference and deeper guidance, see the HSE’s official advice on safety signs (HSE guidance). Poor placement wastes time; poor legibility costs injuries. Don’t compromise on either.

Placement that actually prevents accidents

Put performance over decoration. Place warning signs where people decide what to do next: at the gate to the compound, on the cage door, beside the panel isolator, at the top of the stairwell, or on the approach to the loading bay. Maintain a consistent eye-level centreline—typically 1.4–1.7 m for pedestrian areas—and raise heights where vehicles obstruct sightlines. Use repeaters along long approaches so drivers don’t see a single sign and then forget it fifty metres later. If glare is a problem, angle the board or choose an anti-glare laminate. In noisy or low-light areas, combine visual signage with floor graphics, barriers, and mandatory controls (e.g., hearing protection). Finally, audit your routes quarterly: things move, racking gets re-laid, and new machinery arrives. If a route changes, your signs should move the same day. That’s how you keep risk control real, not theoretical.

Size, materials, and finishes that survive the job

Pick sizes by viewing distance and speed of approach. For outdoor warning signs, larger formats (A3, A2, or custom) work better across yards and compounds; inside plants and corridors, A4 is often sufficient if sightlines are clear. PVC or polypropylene gives you a light, economical board for interiors; foamex and aluminium composite panel (ACP) add rigidity for fences and hoardings; self-adhesive vinyl suits doors, electrical cabinets, and clean rooms. Need heavy-duty? Choose ACP with radius corners and pre-drilled holes; pair with a UV-stable laminate for long sunlight exposure. On floors, use anti-slip over-laminate with a high pendulum test value. All our boards print at high resolution, so symbols stay sharp, and we finish edges neatly so they don’t delaminate in the first winter.

Quick buying guide: pick the right sign first time

If you want speed and consistency, standardise. Start with your hazard register, then map each risk to the correct ISO 7010 symbol. Choose one material family per zone so everything looks intentional. In dry, low-impact corridors, economical PP boards work well; in wash-down food areas, go for laminated vinyl; around plant rooms and perimeters, ACP is the sensible default. Select sizes by viewing distance; bigger is clearer, and clarity prevents incidents. Use durable fixings that suit the substrate: VHB tape on smooth panels, stainless fixings on timber or chain-link, and magnetic backings on steel cabinets. For multi-site roll-outs, build a spec sheet that lists code, legend, material, size, and fixings for each location. When you document that once, you buy fast, store smart, and install without debates on site. You’ll save time, standardise your look, and reduce ordering errors because everyone is reading from the same page. That’s how warning signs stop being an afterthought and become part of your control system. When you standardise your warning signs, supervisors stop improvising with office paper and tape, and audits stop flagging inconsistent symbols.

Most-used hazard legends by sector

Construction typically leads with overhead load, deep excavation, fragile roof, and moving plant. Fabrication shops focus on entanglement, hot surfaces, compressed air, and sharp blades. In warehousing you’ll see pedestrian/vehicle interface risks, slippery floors, and stacked loads—so you’ll specify consistent forklift route markers and complementary caution graphics. Laboratories prioritise biohazard, laser, and corrosive chemical risks; healthcare adds radiation and oxygen enrichment controls. Schools and public buildings require safer glazing, low headroom, and wet floor coverage. For all of these, choose legends that match the actual hazard, not just the nearest guess. If you can’t find an exact symbol, ask us to create compliant custom “supplementary text” panels so the pictogram stays standard while the message is site-specific. That way, your warning signs tell the truth about the risk, and your team responds correctly the first time.

Custom artwork, bilingual text, and asset IDs

Standard pictograms keep you compliant, but supplementary panels make them yours. We add bilingual text, asset IDs, QR codes to SOPs, contractor permit numbers, and area references without crowding the layout. Fonts stay legible; margins stay generous; and the triangle remains dominant, as the standard intends. For multi-lingual sites or public venues, we’ll balance English with the second language you specify and maintain consistent typographic hierarchy across the whole pack. If vandal resistance matters, we offer anti-graffiti laminate so solvent wipes remove paint without ghosting. For clean-rooms and food prep, we use low-tack removable adhesives to prevent residue. Need a serialised run for inspection regimes? We’ll encode unique IDs into the bottom margin so you can audit every board. It’s exactly how custom warning signs should work: compliant first, tailored second, and always readable.

Why EU Signs: British manufacturing, faster lead times, honest pricing

You’re buying safety, not wall decoration. We print in-house on UV flatbed and solvent platforms, we profile-cut on our CNC, and we finish by hand so edges are clean and fixings align. That means tighter QC, reliable timelines, and short-run agility when you need one-offs today and a thousand boards next week. We build repeatable product specs, label every stack, and ship with clear picking notes so installation teams can get on and fit without calling the office. Most importantly, our warning signs use ISO 7010 pictograms, correct yellow/black contrast, and tough substrates that don’t curl or bleach. You get British-made quality, straight talk, and pricing that makes sense for projects and maintenance budgets alike. If you’re consolidating suppliers, we’ll map your estate, rationalise SKUs, and standardise materials so replenishment is faster and cheaper.

Built for durability and sustainability

We choose substrates for performance and footprint. Where possible, we specify recyclable polypropylene and ACP with recyclable cores; for temporary works, we favour materials that can be recovered and reused. Inks are UV-stable and low-odour; laminates are robust yet easy to wipe down. For night-time yards and tunnels, we offer Class RA1 or micro-prismatic options so messages pop under headlights. Fixings include stainless screws, rivets with backing washers, and industrial tapes rated for outdoor use. Because sites change, we also supply replacement panels that slot into existing frames to avoid binning hardware. If sustainability is in scope, we’ll document material choices, recycling routes, and end-of-life handling so your ESG report reflects action, not buzzwords. That’s how you invest in warning signs that last and still support your environmental targets.

Compliant paperwork for audits and RAMS

Auditors expect evidence: standards referenced, sizes justified, and a site plan that shows why each board sits where it sits. We’ll supply product data sheets, material specs, and symbol references to BS 5499 & EN ISO 7010. We can map sign locations on your drawings and cross-reference each position to a risk statement, so your RAMS and signage inventory line up. During re-induction, your teams will see the same symbols on paper and on walls—no mixed messages, no near-miss excuses. If your audit flags small text or faded colours, we’ll upsize and re-laminate; if glare causes legibility issues, we’ll switch finishes. Because the goal isn’t ticking a box; it’s protecting people. When your audit says “legible warning signs at the point of risk,” you’ll already be there.

Get a quote and straightforward trade support

Spec the job once and stop re-explaining it. Send us your hazard list and site plan, and we’ll return a simple schedule: legend, size, material, fixing, and location—ready to sign off and order. We can hold stock for phased projects, pack by area or floor, and label boxes so installers work efficiently. If you need procurement-friendly pricing, we’ll bundle discounts on volume orders of warning signs and combine deliveries with your other safety categories to cut carriage costs. For category expansion, we’ll align your hazard boards with complementary Mandatory and Prohibition ranges so the whole site looks consistent. When you need it fast, say so; we’ll give you a realistic lead time and hit it. If you’re building out a larger safety programme, we’ll help you rationalise SKUs and standardise templates for custom warning signs across all sites. That way, you protect people, satisfy auditors, and make purchasing painless—today and next quarter.

Explore our full safety range here: Health and Safety Signs. Pair your hazard boards with clear blue-circle instructions via our Mandatory Signs. Ready to brief us or need a bulk quote? Contact us and we’ll get it moving.

Shop by Categories

- Health and Safety Signs

- First Aid Signs

- Construction Signs

- Warning Signs

- Footpath Signs

- Combination Safety Signs

- Protective Equipment Signs

- Office Signs

- Social Distancing Essentials

- CCTV in Operation Signs

- Information Signs

- Garage Signs

- Health & Safety Posters

- Door Signs

- Health and Safety Stickers

- Custom Printed Banners

- Printed Business Stationery

- Workwear

- Deals